Crankshafts are the beating heart of an engine, and they are also the most critical and stressed component of the rotating assembly. As a result, they must be precision parts in addition to being solid. The main and rod journals must be precision machined not only in terms of scale and roundness, but also in terms of the location of those journals that are offset from the rotation axis.

Crankshaft Machining Combines Precision And Speed

You change the stroke length if the direction of a rod journal is off on one axis. The timing of the piston entering the top dead centre is altered if you’re off the other axis. Even though the devices in this video make it look like child’s play, offset turning is a difficult method for those unfamiliar with the use of a lathe.

Manufacturing Design and Engineering

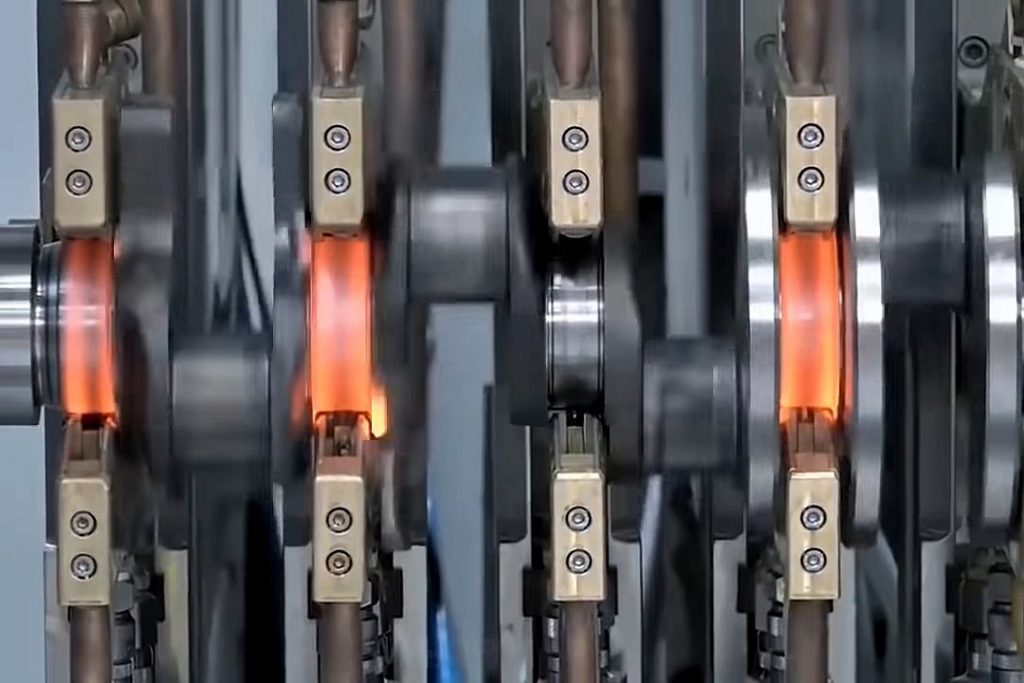

With the progress in technology and hardware, these machines can now finish-polish each journal independently of the others, a job that normally involves a human touch. One of the coolest features is a technology we didn’t even know existed: induction hardening for individual journals (and built-in-quenching). Perhaps by limiting the intense heat to a single journal and minimising any distortion in the shape of its crankshaft by sequencing the heating and quenching of individual journals.

Perhaps by keeping the extreme heat confined to the particular journal, and by mitigating any distortion in the form of the crankshaft in the order in which individual journals are heated and quenched.

There is only the sheer elegance of the mechanical dance performed by the numerous clamps, probes, drills, and machining tools, in addition to all the technical marvels involved in these automated crankshaft manufacturing devices, as they convert steel into thin shavings and turn a single cast or forged hunk of metal into a precision piece of automotive equipment. So just sit back and enjoy your show.

Recent Posts

- Important Considerations in CNC Machining Quality Inspection

- Important Considerations in CNC Machining Quality Inspection

- CNC Machining

- Metal Fabrication

- Welding Services

- CNC Milling

- Important Considerations in CNC Machining Quality Inspection

- Custom steel metal fabrication

- Conventional turning to robotics for multifunctional machining: major changes in output

- 7 Reasons Why CNC Machining Wins Over Traditional Machining

- structural steel fabricators oakville

- Multitasking Machines

- CNC Crankshaft Machining

- 10 Ways to Save on CNC Machining

- CNC machining Services

- Steel Fabrication Association Canada