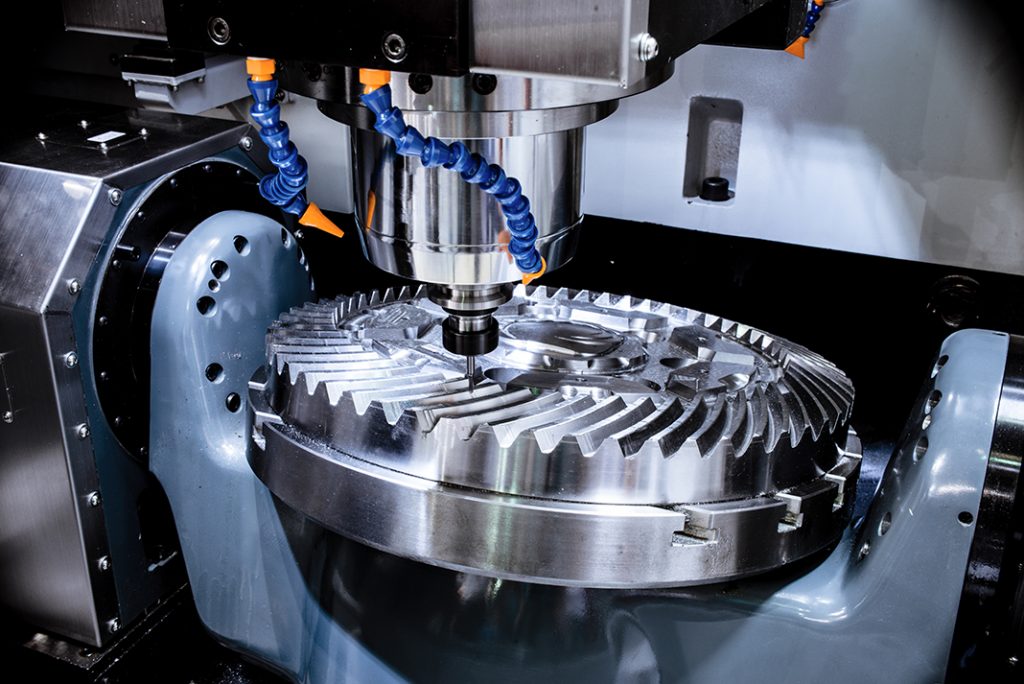

Offsets in CNC Milling.

Offsets are literally a platform for programming. And it doesn’t require fixing the machine. In some cases, the actual machine is additionally unknown. this is often actually a Cartesian system.

But the most difference is that during this system, the Z-axis lies on the spindle, and therefore the angle between x and y axes is 90 degrees. When a machine is within the initial stage, all of the axes are during a position of utmost travel.

There are two types of offsets required for work.

Tool Offset

Tool offset is nothing but the required values and measures we use to style a tool and shift the position of the tool. If we all know the precise tool offsets, we will find the precise machining start line

Work Offset

For adjusting the master tool, the tool offset is the ideal one. On the opposite hand, you’ll use the work offset to regulate the program. When the conditions and therefore the targets change, we’ve to vary the work offset. On the opposite hand, the tool offset remains equivalent.

Tool offsets -Depend on the change in geometrical shapes and sizes.

Work offsets- depend upon the workload and therefore the required output.

Tool offset has three main components. On the other hand, the work offset has eight different working components. On the opposite hand, the work offset is the general representation of the specifications of workpieces. And if we’d like to vary those specifications, then the work offset takes an important role.

Know about CNC Machining : Click Here

The tool offset lies between the spindle nose and the leading edge. On the opposite hand, the work offset lies between the spindle nose and therefore the point of reference. In the master tool, if the tool specifications change, then it becomes difficult to use the work offset without adjusting the tool offset. meaning neither the tool offset nor the work offset can operate without one other. Work offsets are literally the functions of inputs and outputs. On the opposite hand, tool offsets are the measurements of the procedures between the inputs and outputs.

Know More : Click Here