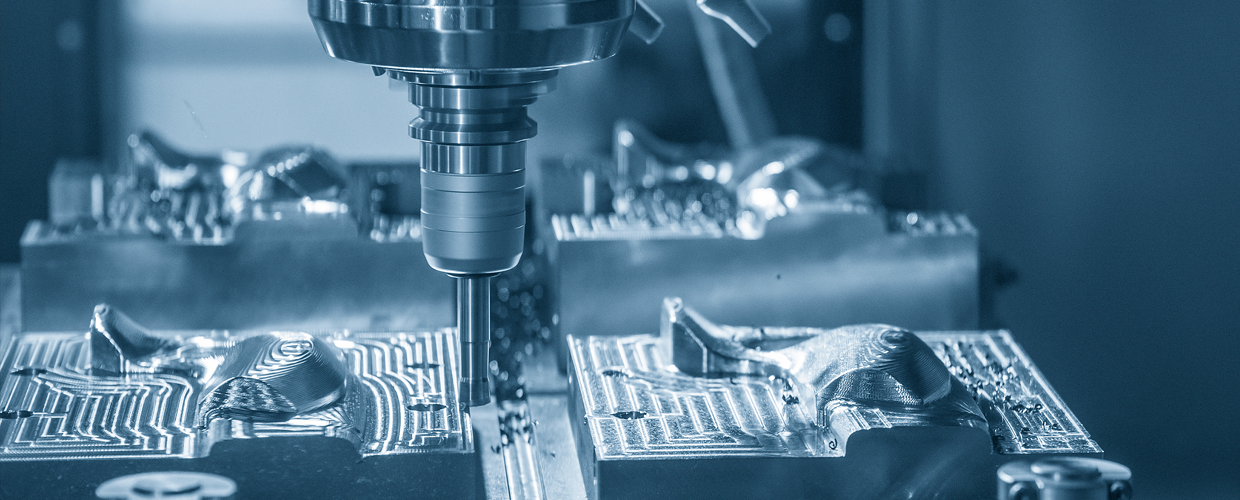

CNC Milling

GRAPCO TOOLING INC – Industry Leader in Precision Machining

CNC Milling: In the industrial manufacturing industry today, computers are used to perform computer numerical control (CNC), controlling both the movement and operation of cutting machines such as lathes and mills.

Know more about CNC Milling

We have multiple CNC milling equipment and skilled programmers, machinists, and operators and are equipped with the best software, tools, and training in the industry.

We will meet all of your milling specifications on time with our multi-axis milling capabilities.

We can handle larger or smaller parts.

We provide only Quality Machining Tools

We make and sell machining tools and equipment. We use advanced machining tools and systems for the following custom machining services,

Boring

CNC Turning

Drilling

Lifting

CNC Milling

Welding and more

Cutting materials into goods with milling machines and shaping them. There are two basic types of CNC milling machines: horizontal and vertical, which refer to the direction of the spindle of the cutting tool, involving the movement of the workpiece against the rotating blade, the latter of which can be cut on both its flanks and its edge.

Advantages of CNC Machining

If you employ conventional machines, machining shop, or business, you recognize that they are doing some benefits. So why not consider adding one to your production processes? Here are a couple of advantages of CNC machines.

Extensive Experience and Skills Not Required

The production quality of those machines eliminates human error which will occur during production, and that they are much easier to take care of also. Only minimal training is important to maximize production.

Easily Replicate Products

Do you have high production quotas to meet? Program your CNC system for mass production and duplication of high-quality goods.

Cut Labor Costs

Hire fewer employees, while maintaining high production levels. it’s a worthwhile business investment for your company which will allow you to scale back costs.

Increase Your Production Options with CNC Software

Quickly manufacture complex products that can’t be made using conventional machinery. Software updates also are available for improved functionality.

Stimulate Your Ideas, Save Time, and Money

Since there’s no got to create a prototype, simply utilize your CNC Software to simulate your ideas and release valuable labor time.

Our years of experience accompany high standards. Contact us to urge a quote for your next project, big or small.

Get in touch with us

FIRST NAME *

LAST NAME *

EMAIL ADDRESS *

PHONE NUMBER

SUBJECT

HOW CAN WE HELP?