Our Services

In business for over 10 years, GRAPCO Tooling Inc are specialized in high precision machining of components. We boasts state-of-the-art technology and only the most qualified personnel to tackle projects of all shapes and sizes. Our facility has experienced, skilled and professional staff, knowledgeable in all aspects of building precision components and related products.

At GRAPCO, we ensure that our machined parts, assembled parts, services and support provided to our customers are the highest quality in the industry.

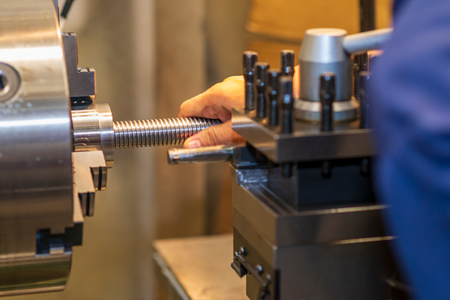

CNC MACHINING WITH PRECISION

To meet your specific parts specifications, Astro Machine Works offers a wide range of precision machining services. With regular scheduled launches, we specialise in single part prototyping, short to medium production runs, and special blanket order arrangements.

As well as wire-EDM and water jet and laser cutting capacities, we have a total complement of computerised and manual milling and turning centres. Our CNC department has the ability to import client drawing files from anywhere in the world, equipped with MasterCam CAD/CAM software. Astro has the experience to provide the results you expect, whether it’s machining complicated components, jigs, fixtures, or gauges, or fixing or changing parts.

We have a structured capital investment strategy that includes continued investment in computerised machine tools and other state-of-the-art technology to ensure that we keep pace with our clients’ needs.

WELDING AND FABRICATION

A specialty built from our machine-building roots is welding and manufacturing. Customers enjoyed the quality of our work on the machines we designed for them and started to request our services in this field.

Our team of qualified welders from AWS D1.1 and ASME Section IX are proficient in welding all forms of carbon steel, stainless steel, aluminium and a variety of specialty alloys, including Inconel 718 and Nytronic 60. All structural types are treated, including the channel, angle, beam, tubes, and plates.

In the medical, pharmaceutical, food processing, packaging, and nuclear energy sectors, we work extensively with businesses. We are also aware of the strict welding requirements expected in these industries and work with them on a daily basis. Astro Machine has the potential to work with different requirements such as food grades for GMP and FDA. All the secondary support services associated with this level of welding complexity are provided by us such as:

Passivating

Electro-poliage

Penetrant examination of Dye

Testing of Magnetic Particles

Processes for industry-specific cleaning

Systems for Panel Wiring and Monitoring

For all applications, Astro Machine Works, Inc. constructs control cabinets to customer requirements. Many customers have come to rely on us for their panel wiring and control system needs due to the extensive panel and control wiring needed in the production of our custom machinery. The main control cabinets, operator stations, and a variety of on-board” wiring and connections are supplied with full wiring. This requires daily wiring of PLCs, as well as experience with touch screen technology and servo drive technologies. Our clients appreciate our custom wired panel layout and arrangement, including the completeness and appearance of our labelling and bundling.